UAV Prototyping Framework

Problem

Traditional UAV prototyping is costly and time-consuming, relying on physical build-test-crash cycles that slow down iteration and increase expenses.

Solution

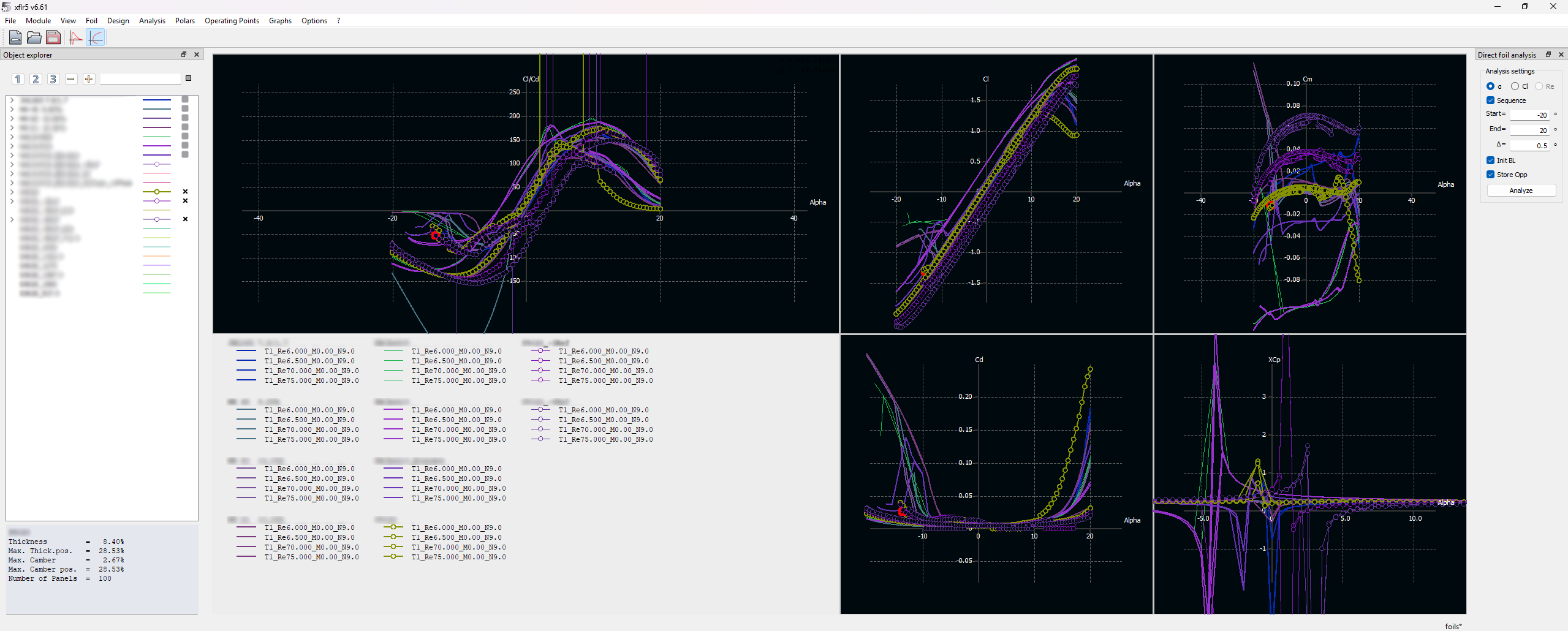

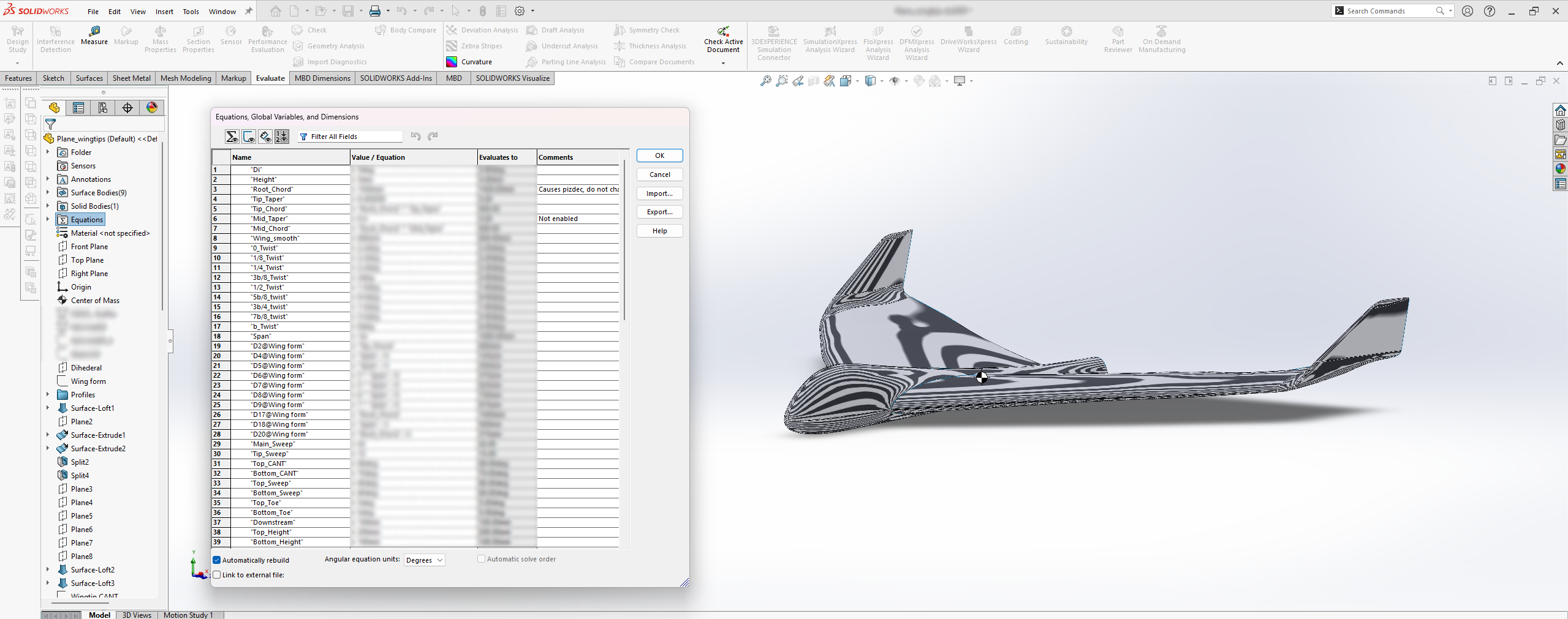

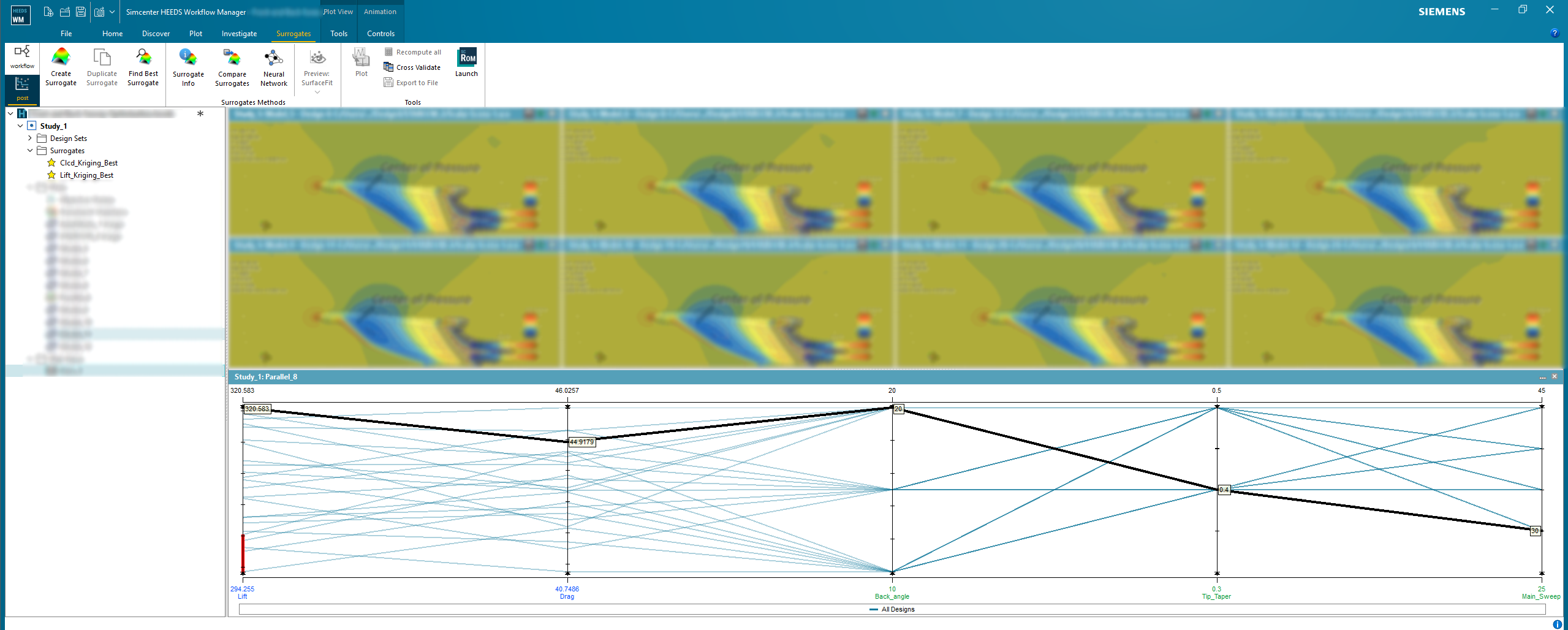

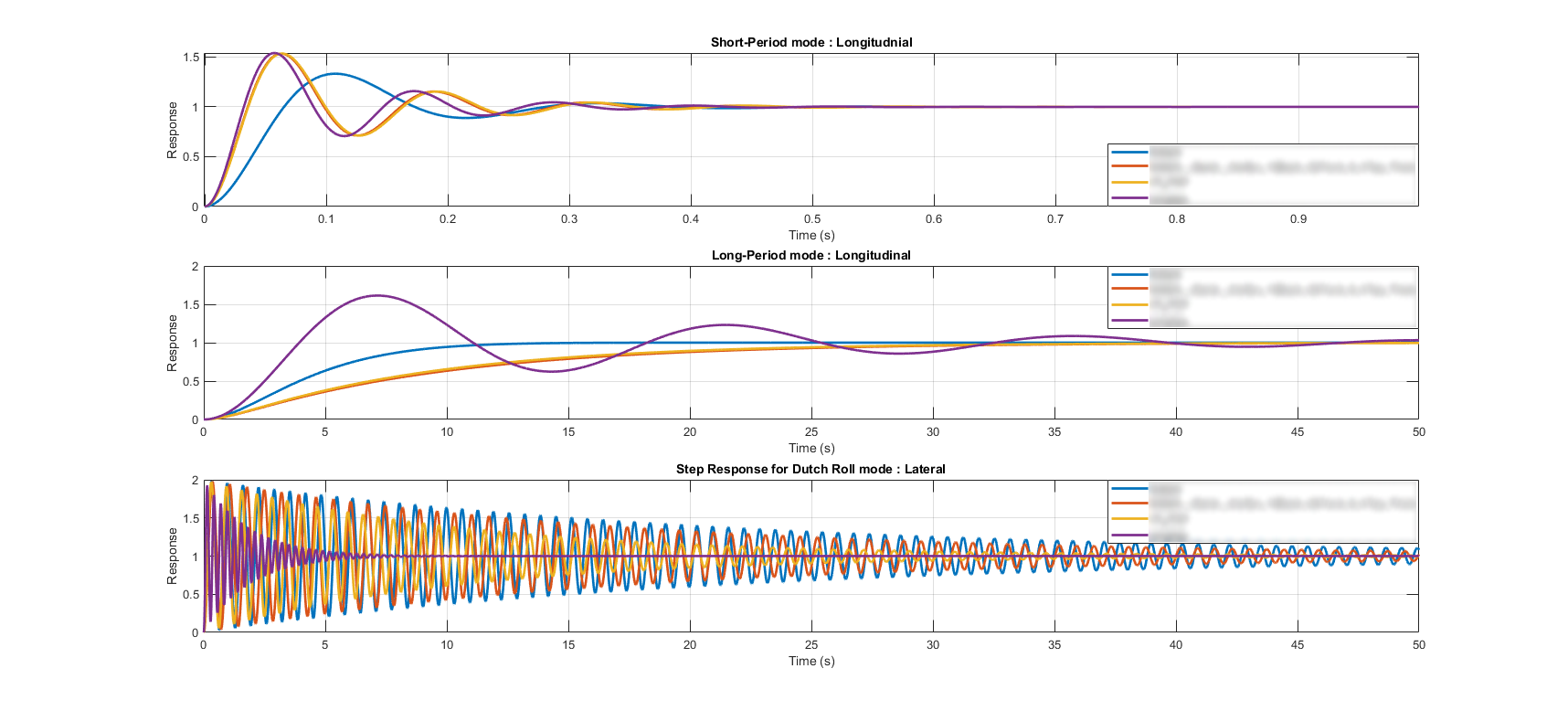

Developed a parametric flying-wing UAV design in SolidWorks, integrated with Star-CCM+ and HEEDS for automated optimization of wing geometry (span, twist, sweep). Conducted a preliminary airfoil analysis using XFLR5 and aerodynamic and stability analyses and Design Manager, then created MATLAB state-space model to assess flight stability. Optimized structural design in AN SYS Mechanical for manufacturability and material efficiency.

Impact

Completed a validated UAV prototype in 3 months-significantly reducing development time and cost compared to standard methodswhile creating a reusable, automated workflow adaptable to future UAV models.

Project information

- Category Aerial Vehicles

- Client Inteligent Defense Solutions, Armenia, Yerevan

- Project duration May, 2025 - Present

- Skills used SolidWorks (CAD), Star-CCM+ (CFD), HEEDS (Workflow optimisation), Ansys Mechanical (FEA), XFLR5 (Airfoil Analysis), MATLAB (System Analysis), Design for Manufacturability (CNC, Composites)