FSAE Rear Wing

Design

Problem

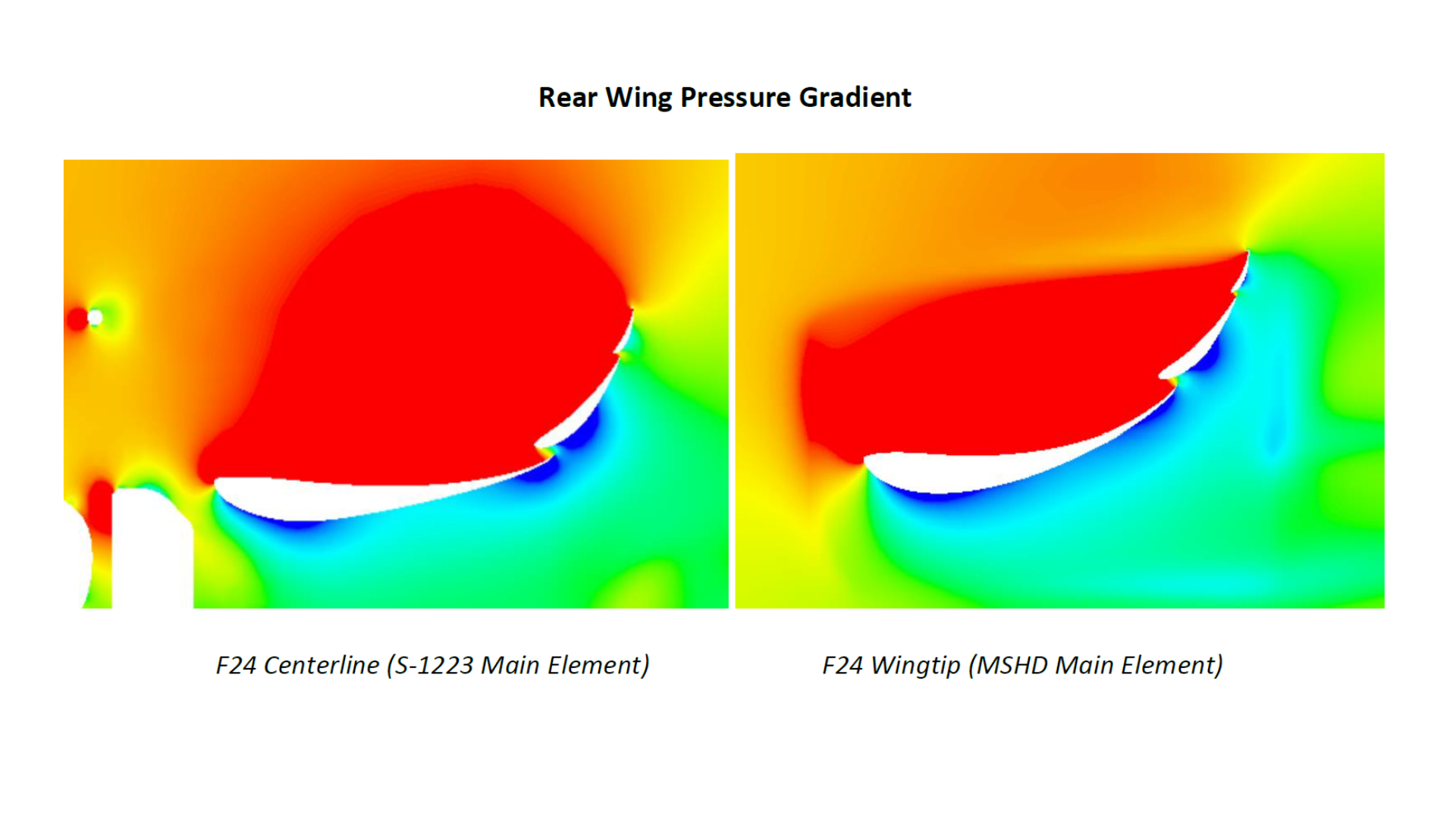

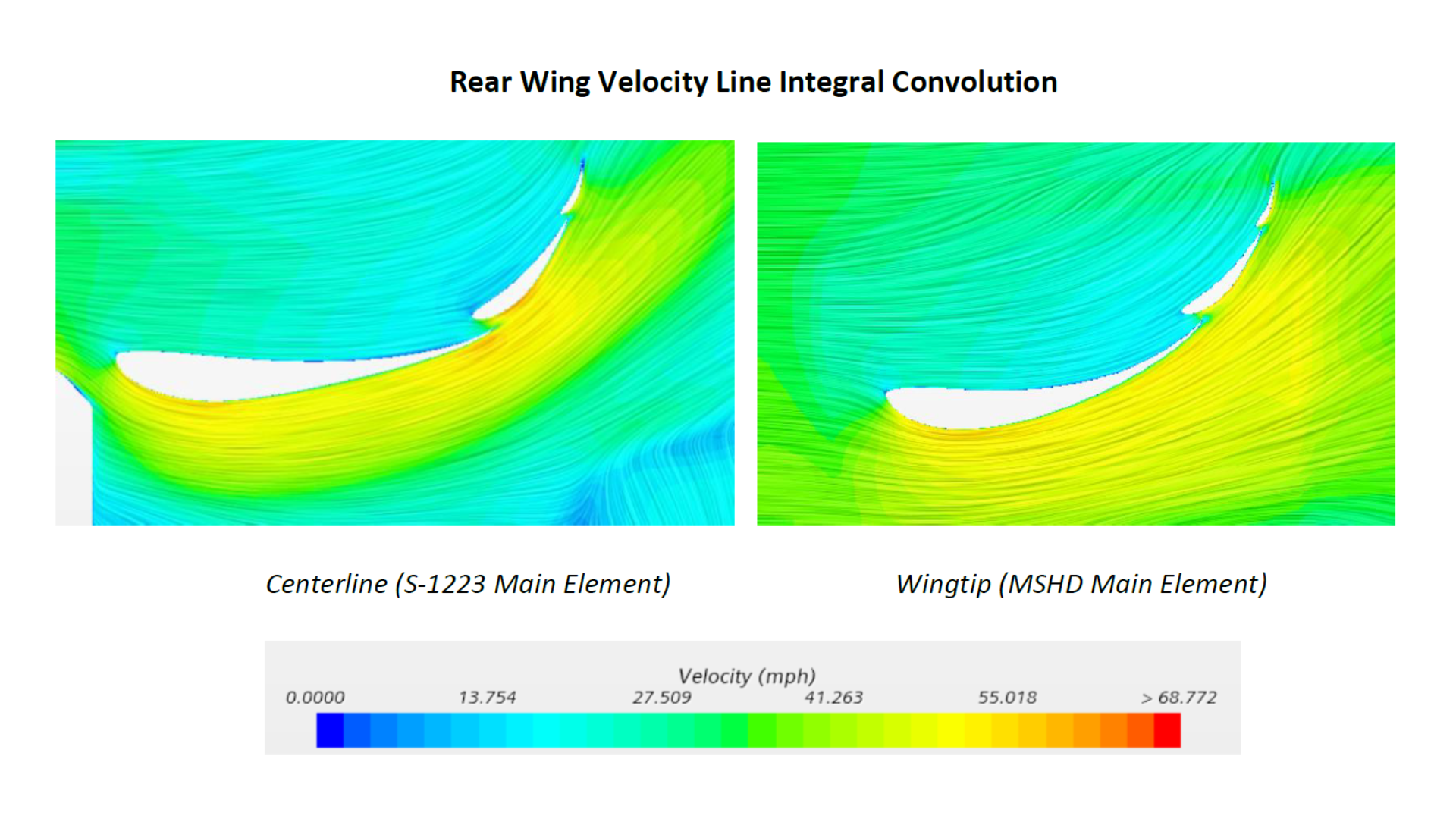

New rule changes placed the driver’s headrest in the airflow path, requiring a rear wing redesign that could maintain aerodynamic balance. The wing also needed to generate sufficient downforce to counteract the front wing while avoiding flow separation across multiple speeds.

Solution

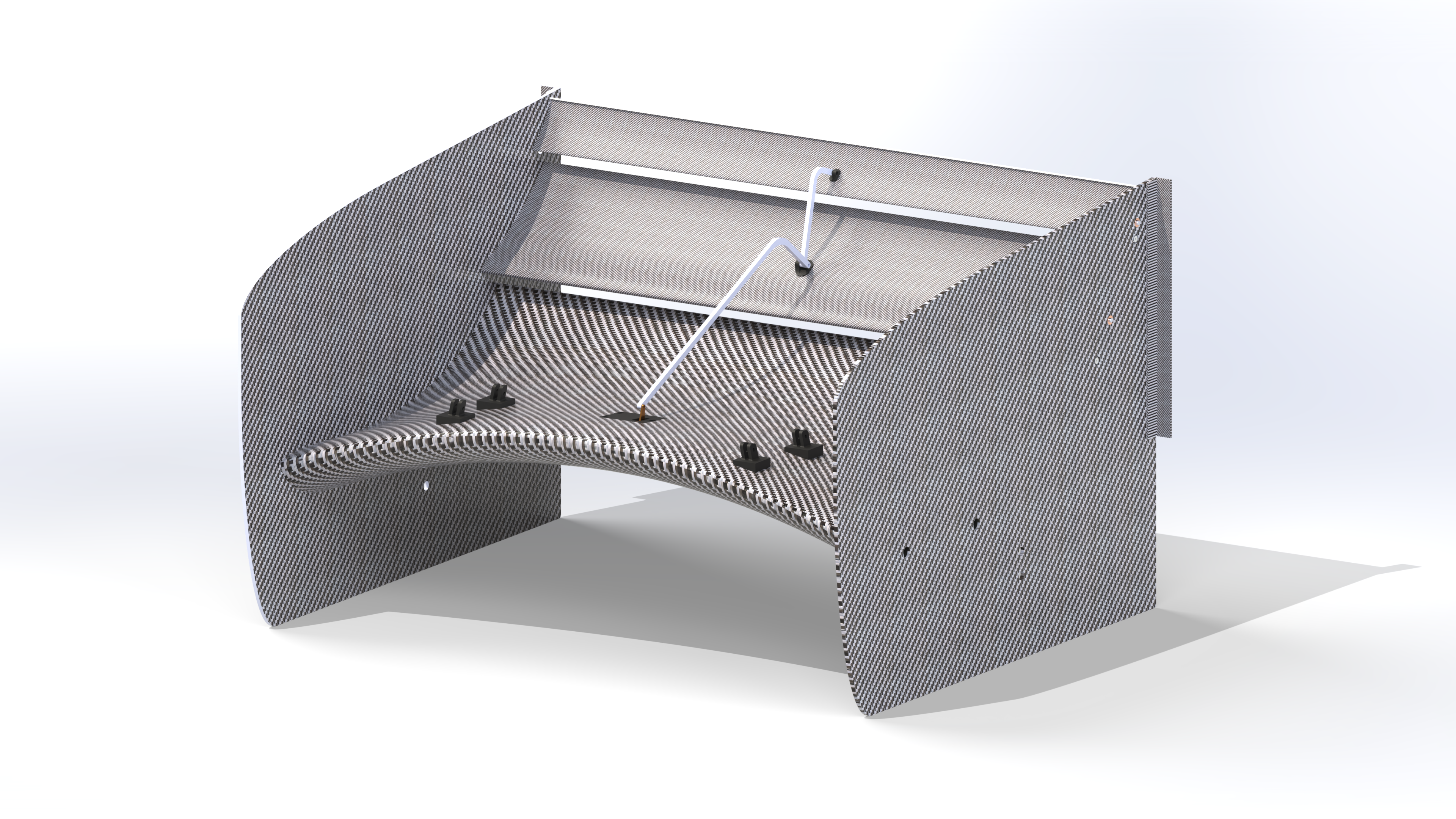

Modeled a three-element cascading rear wing in SolidWorks. Used Star-CCM+ with Design Manager to run CFD analyses and optimize element placement for six design speeds. Implemented a 3D curved main element to route airflow around the headrest, transitioning from high-camber airfoils at the edges to lower-camber airfoils in the center.

Impact

Created a regulation-compliant, optimized rear wing that maintained efficiency and stability, shifted the center of pressure rearward, and improved overall aerodynamic balance and vehicle performance.

Manufacturing

Problem

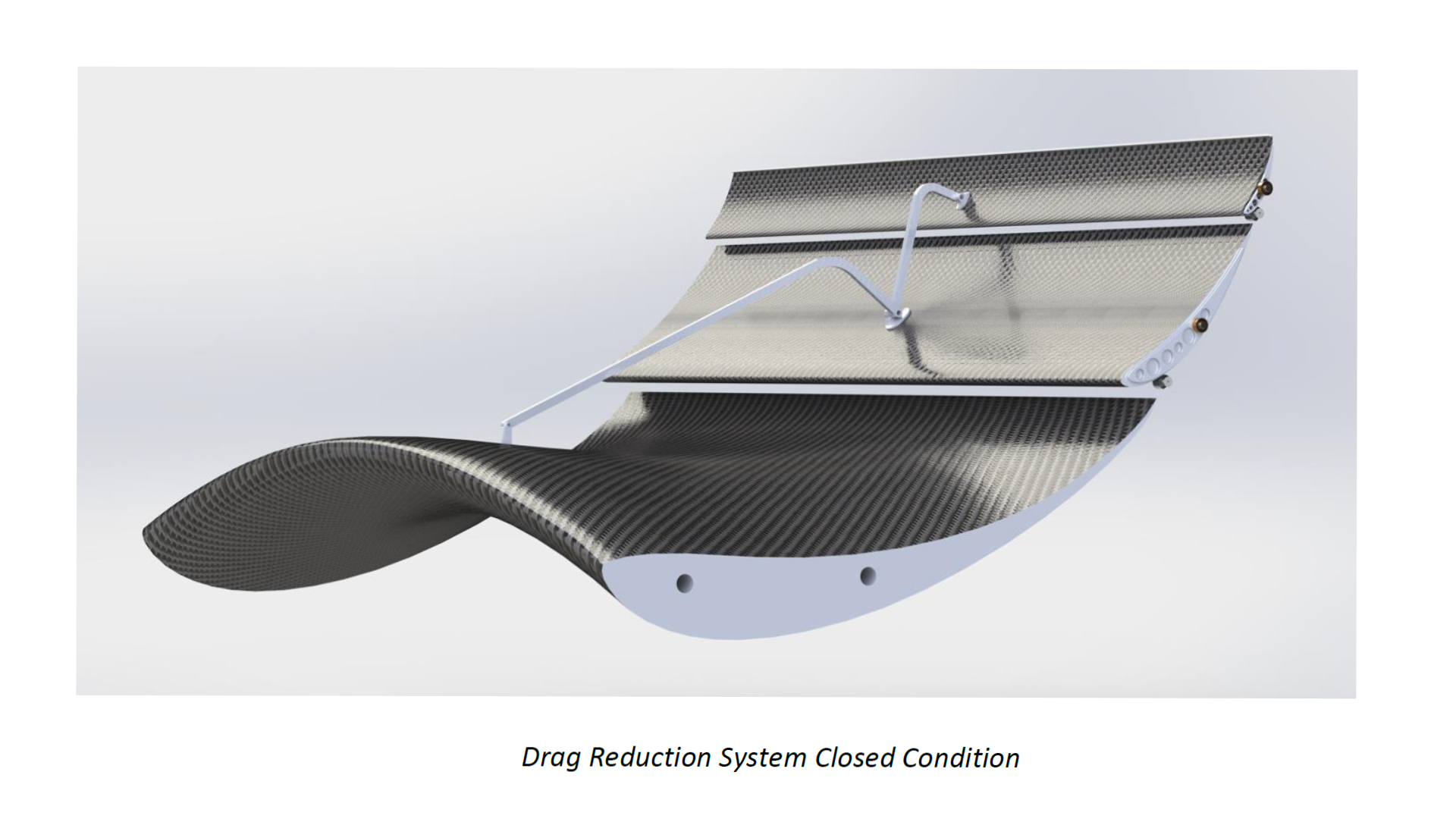

The rear wing’s 3D curvature, designed to clear the driver’s headrest and interact with cleaner airflow, created manufacturing challenges. A drag-reduction solution(DRS) was also required to balance performance at high speeds.

Solution

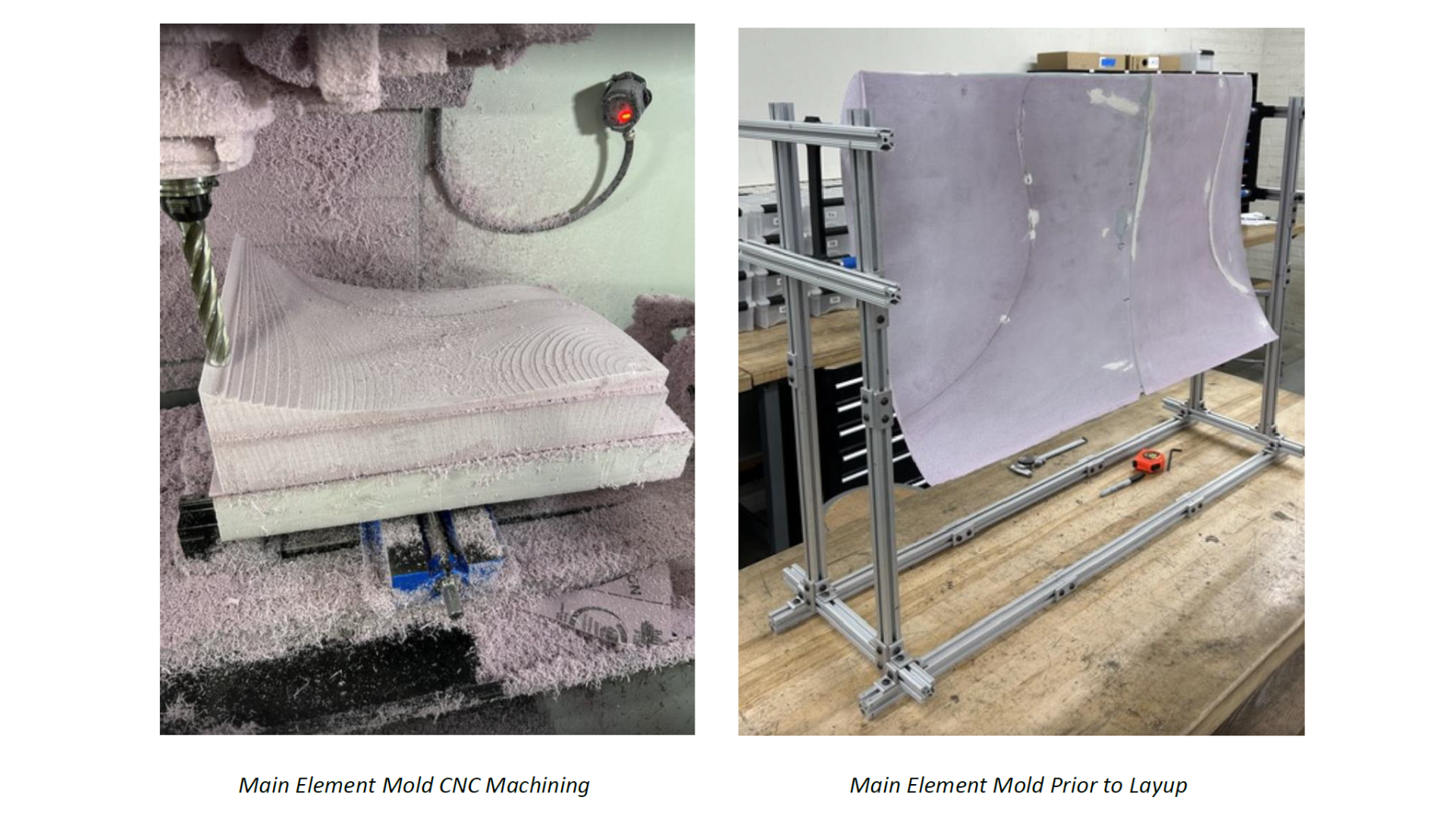

Implemented a DRS system to minimize drag when downforce was not needed. Modeled CNC toolpaths in Fusion 360 to machine two halves of a male mold (instead of traditional male + female molds) for the carbon fiber layup. The mold was suspended for one-piece wrapping, and peel ply was applied during vacuum bagging to replace Mylar.

Impact

Achieved a cost- and time-efficient manufacturing process for the 3D curved rear wing, while maintaining aerodynamic performance and compliance with racing constraints.

Project information

- Category Composite Structures

- Client Gator Motorsports FSAE, UF

- Project duration June, 2023 - May, 2024

- Skills used SolidWorks (CAD), Star-CCM+ (CFD), Fusion 360 (CNC), Matlab (Reverse Kinematics), Design for Manufacturability(CNC, Composites, FDM)