Lumbar Spine Implant

Problem

Spinal fusion implants require stable fixation between lumbar joints, but existing solutions are limited by manufacturing constraints and insertion size.

Solution

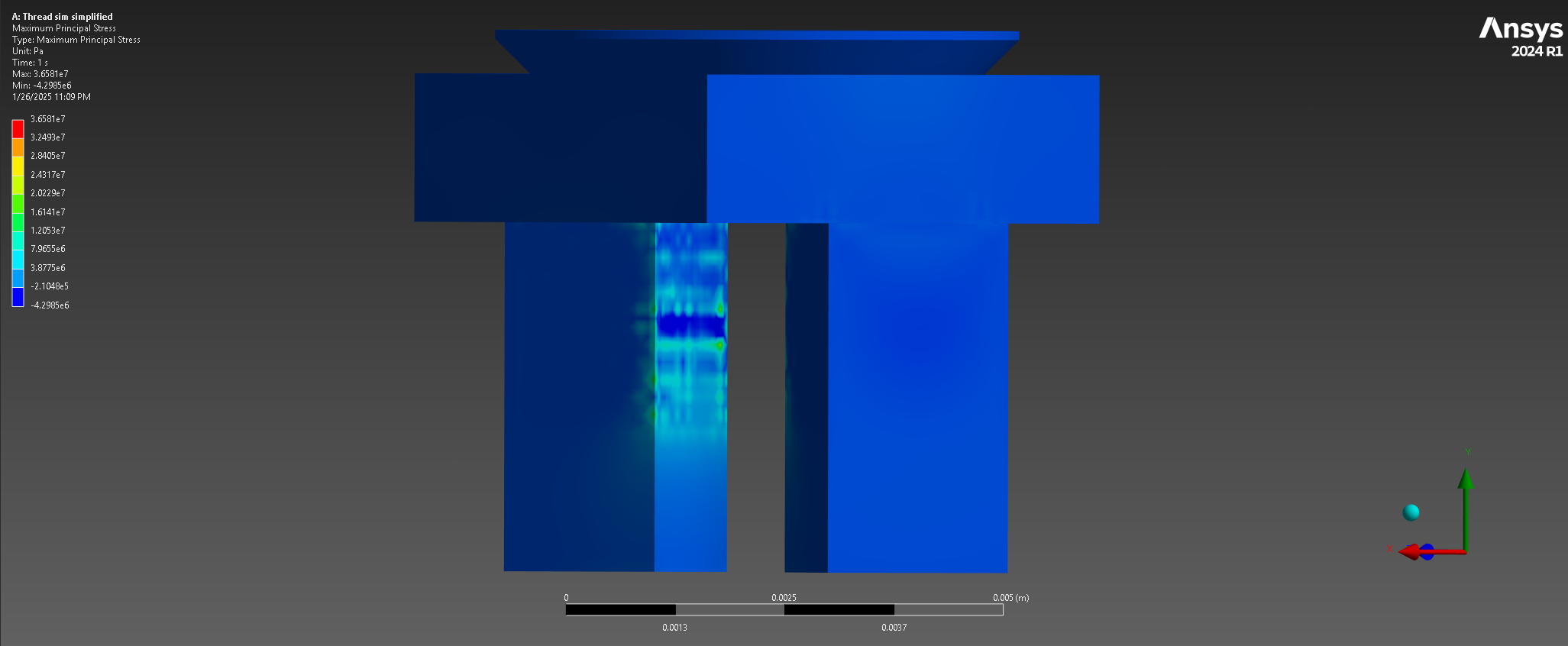

Designed a three-part implant with a rotatable claw, locking mechanism, and press-fit design. Used SolidWorks for design, and validated with torsional and thread preload analysis in Ansys. Manufactured using Direct Metal Laser Sintering (DMLS) and CNC milling for the threads.

Impact

All the additional tools needed for the insertion were designed with testing in mind. Further improvements are to come after the validation process for the first high fidelity prototype is complete.

Project information

- Category Biological Implants

- Client Sriharan Siva MD, UF

- Project duration Sep, 2024 - Present

- Skills used SolidWorks (CAD), Ansys Mechanical (FEA), Design for Manufacturability (DMLS)